Overview

This product measures four independent channels of airflow velocity using sensors based on the principle of airflow vortex shedding. It has been developed and tested on an eight inch pipe for airflow velocities from between 50 CFM to over 900 CFM with a better than 1% accuracy. Further with its use of digital signal processing techniques it has been shown to be resistant to turbulent flow disturbances affecting this accuracy.

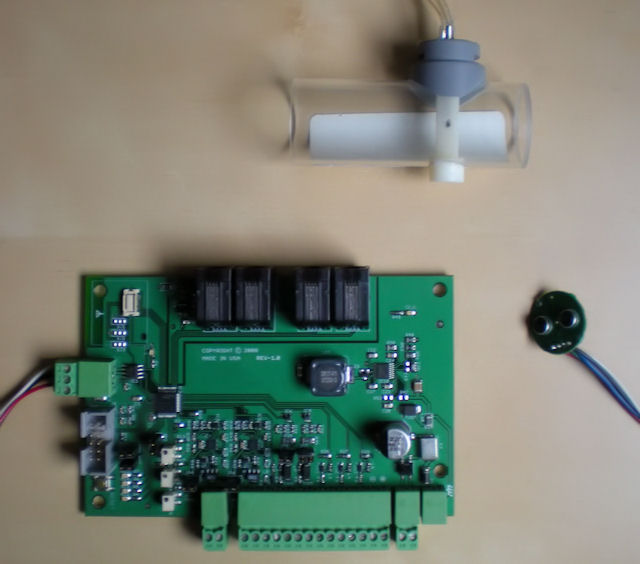

The design includes a PID controller, several channels of general purpose analog inputs and outputs that can be set up to operate in the zero to ten volt range, or to use current-loop 4 to 20ma signals. It also has several digital I/O ports available. For network communication a RS-485 network interface with a BACnet MS/TP protocol stack is provided. All interface lines are protected from electrical overloads. An 2.4 GHz RF mesh network communication link is also available.

Functional electronics, and ready firmware for all the facets of this system have been developed. The electronics is the current state of the art using an advanced in-system programmable, mixed-signal System-on-Chip 100 MHz processor with an integral DSP MAC unit. The system includes external op-amp signal conditioning boards attached to each of the up to four frequency sensor inputs. The system is designed for 24 volts AC and draws low power, but it can operate over a wide voltage input range from 3.3 to 44 Volts AC or DC. The power inputs are protected from wrong polarity, and the inadvertent application of AC line voltages.

Detailed Technical Description

A small four layer split analog and digital ground plane circuit board design has been completed that contains a switching power supply, interfaces to the sensor front ends, and the analog, digital, and RF interfaces. This system makes the precise realtime frequency measurements of the vortex signal conditioning boards' 50 Hz to 1.6 kHz sinewave outputs.

As mentioned the system has RS-485 communications used as the electrical layer of the BACnet (Building Automation and Control) MS/TP (Master Slave/Token Passing) protocol and data encapsulation. The network is specifically tailored to building and control industry, supporting objects defined by the standards committee for this exact industry.

- Firmware is in ANSI standard C with assembler where required.

- Programming is written according to structured and variable naming standard guidelines.

- System design is modularized.

Conclusion

This electronics is applicable to many airflow instrumentation and control applications. This single board, flow sensors, and a servo motor controlled damper are all that is required to implement a set point determined feedback controlled airflow rate. A pair of system boards commanded to different flow rates can be used to implement a complete air pressure tracking controller.

Central to the design is the industry standard network and data encoding. Using BACnet other devices from other manufactures can share the same network and interact with this sensor device.